| Item | Specification |

| Dielectric withstand voltage | 500V AC, 1min (between all terminals and ground) |

| Analog circuits | 24V DC ± 10%, 55mA |

| Digital circuits | 5V DC, 90mA (internal power supply from the main unit) |

| Centigrade (°C)/Fahrenheit (°F) | Both °C and °F are available by reading the appropriate buffer memory(BFM). |

| Input signal | Thermocouple: Type K or J (either can be used for each channel), 4 channels

|

| Rated temperature range(°C) | Type K:-100℃ to +1200℃ Type J:-100℃ to +600℃ |

| Rated temperature range(°F) | Type K:-148℉to +2192℉ Type J:-148℉ to +1112℉ |

| Digital output(°C) | Type K:-1000 to 12000 Type J:-1000 to 6000 |

| Digital output(°F) | Type K:-1480 to 21920 Type J:-1480 to 11120 |

| Digital output | 12-bit conversion ,save as complement of 2 in 16 bits |

| Overall accuracy | ± (0.5% full scale +1°C) Freezing point of pure water 0°C / 32°F |

| Conversion speed | (240ms ± 2%) × 4 channels (unused channels are not converted) |

| CE Certification | CE marked |

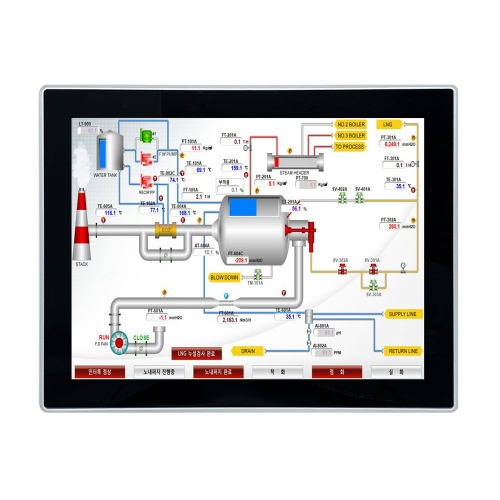

The Application:

Battery Drying Oven, its working process includes, warming – cooling – vacuum – forcing – nitrogen filling. The project has total 100 processes comprises two different process cycles. Data monitoring, data acquiring, PID Auto-tuning (self-tuning). Measurement of Temperature at different 12 points. There difference in the temperature at upper, lower, middle, center of the oven. So, temperature gradient is there and homogeneity of the oven is affected.

V-BOX WECON

V-BOX WECON  MÁY TÍNH CÔNG NGHIỆP HOLA

MÁY TÍNH CÔNG NGHIỆP HOLA  PHẦN MỀM

PHẦN MỀM

0984.162.317

0984.162.317